Applications of antibacterial fabrics

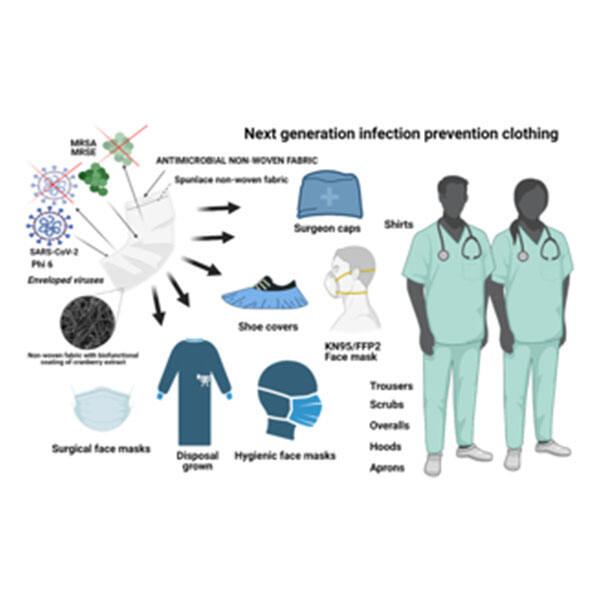

Medical: Antimicrobial materials can be used in medical bedding, privacy curtains, medical uniforms, and hospital gowns to significantly reduce the risk of infection. Hotels: Antimicrobial materials can be used in hotel bedding and guest towels to create a clean environment. Apparel: Antimicrobial properties can be added to clothing, especially sportswear, to control sweat odor and keep clothes fresh during exercise. Outdoor textiles: Antimicrobial materials can be added to awnings, canopies, and outdoor furniture to extend their lifespan and reduce the amount of bacteria that come into contact with the human body. Cleanrooms and laboratories: Antimicrobial materials can be used in places with strict hygiene requirements to prevent microbial contamination. Packaging and textile accessories: Antimicrobial bags, towels, or bathrobes can be used to prevent further bacterial growth and maintain hygiene standards.

100% Antibacterial fabric

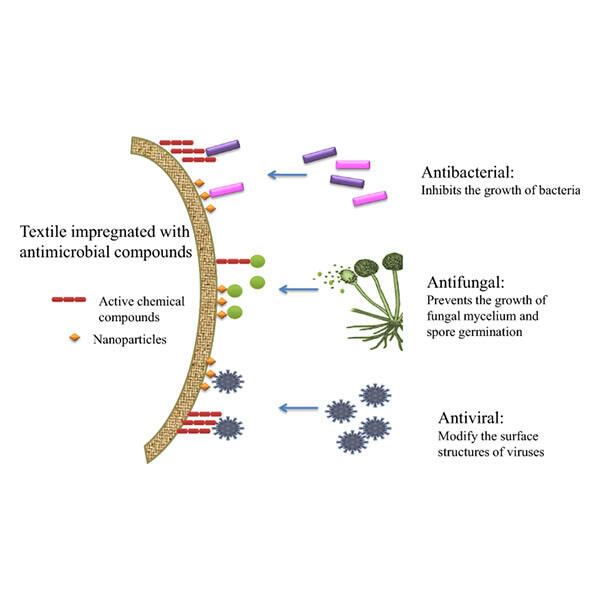

"100% antibacterial fabric" doesn't necessarily refer to bacteria-free fabrics; rather, engineered fabrics can be designed with extremely high antibacterial effectiveness - sometimes surpassing 99.9999% reduction of bacteria within 24 hours! Zin nanocomposite textiles fabricated using in situ grown zinc nanoparticles in their fabric have demonstrated antibacterial activity of 99.99% to 99.9999% within 24 hours and this protection lasts through 50 or 100 wash cycles demonstrating long-term durability of antibacterial action without significant loss in efficacy or efficacy loss over time. Other advanced antibacterial fabrics use silver ion technology (not nanoparticles) for long-lasting antimicrobial defense against bacteria, fungus, and algae growth on textile surfaces. This keeps fabrics clean, fresh, hygienic, and safe against skin allergies for extended periods. Incorporating techniques like Swiss HeiQ Viroblock into high-tech apparel that can be reused multiple times after washing without losing effectiveness is also available. Antimicrobial finishes contain 100% plant-derived active ingredients which offer antibacterial and antimicrobial activity to fabrics while remaining eco-friendly and sustainable, prolonging freshness and reducing washing frequency.

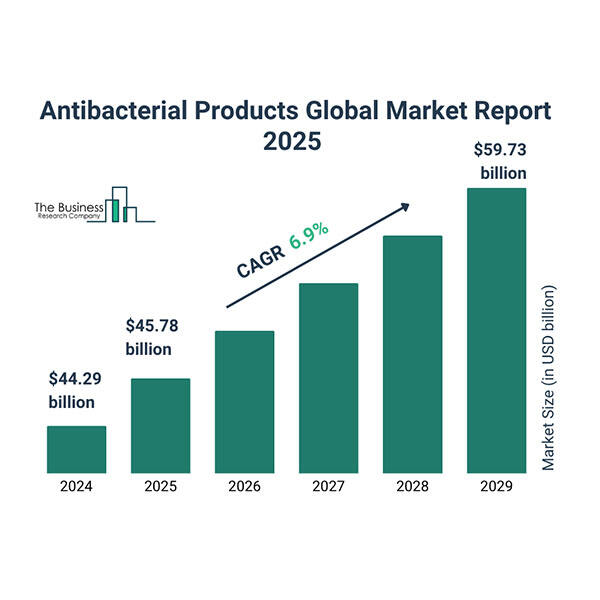

The Rising Demand for Antibacterial Fabric

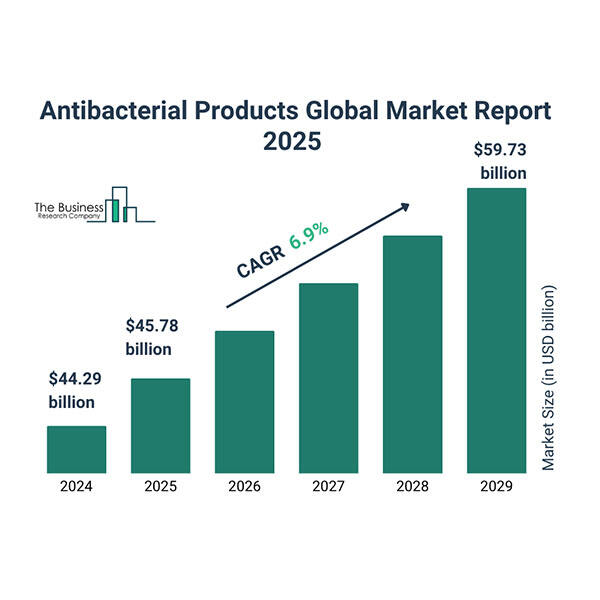

Driven by increasing healthcare needs, higher hygiene standards, and the growing need for infection control across various industries, the demand for antimicrobial fabrics is steadily increasing. The global antimicrobial fabric market is estimated to be approximately $2.5 billion in 2025, with a projected compound annual growth rate of 7-10% through 2033. This rapid growth is driven by factors such as the alarming rise in the prevalence of healthcare-associated infections (HAIs) as consumers become more aware of hygiene, and the expanding application of antimicrobial fabrics in medical textiles, apparel (sportswear/underwear), and home furnishings (such as bedding/upholstery). Technological advances such as nanotechnology (e.g., silver and zinc oxide nanoparticles) and bio-based antimicrobial agents are driving market expansion by producing more effective, durable, and sustainable antimicrobial fabrics. Regulatory requirements are also contributing to their adoption. Regionally, North America and Europe currently lead in healthcare infrastructure development and hygiene awareness; however, the market in Asia Pacific is expected to expand faster due to rising disposable incomes and improved medical facilities. In addition to opportunities, antimicrobial textiles also face challenges, including their higher cost than traditional fabrics, as well as concerns about long-term safety and resistance to certain agents; however, ongoing research and development is focused on finding more sustainable and cost-effective solutions.

Hot News

Hot News