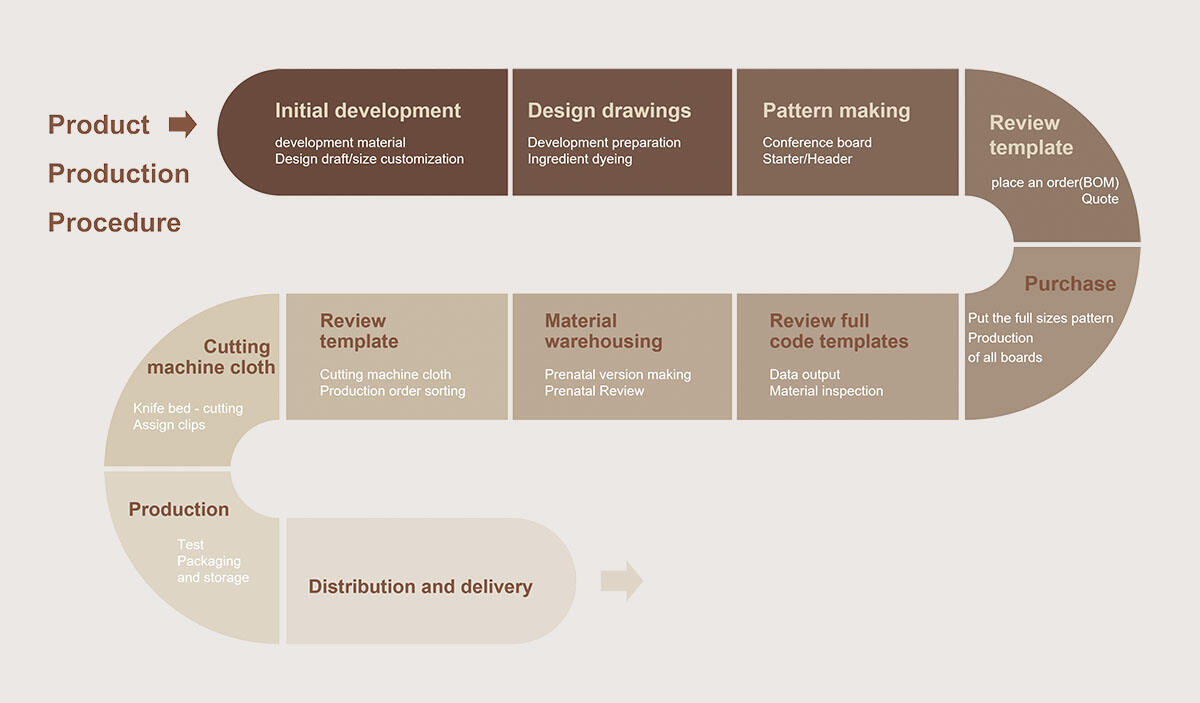

쉐이프웨어의 최고 품질을 보장하기 위해서는 제조 과정의 모든 단계에 꼼꼼한 주의가 필요합니다. S-Shaper는 각 제품이 처음부터 끝까지 뛰어난 기준을 유지하도록 엄격한 다단계 절차를 거쳐 제작됩니다.

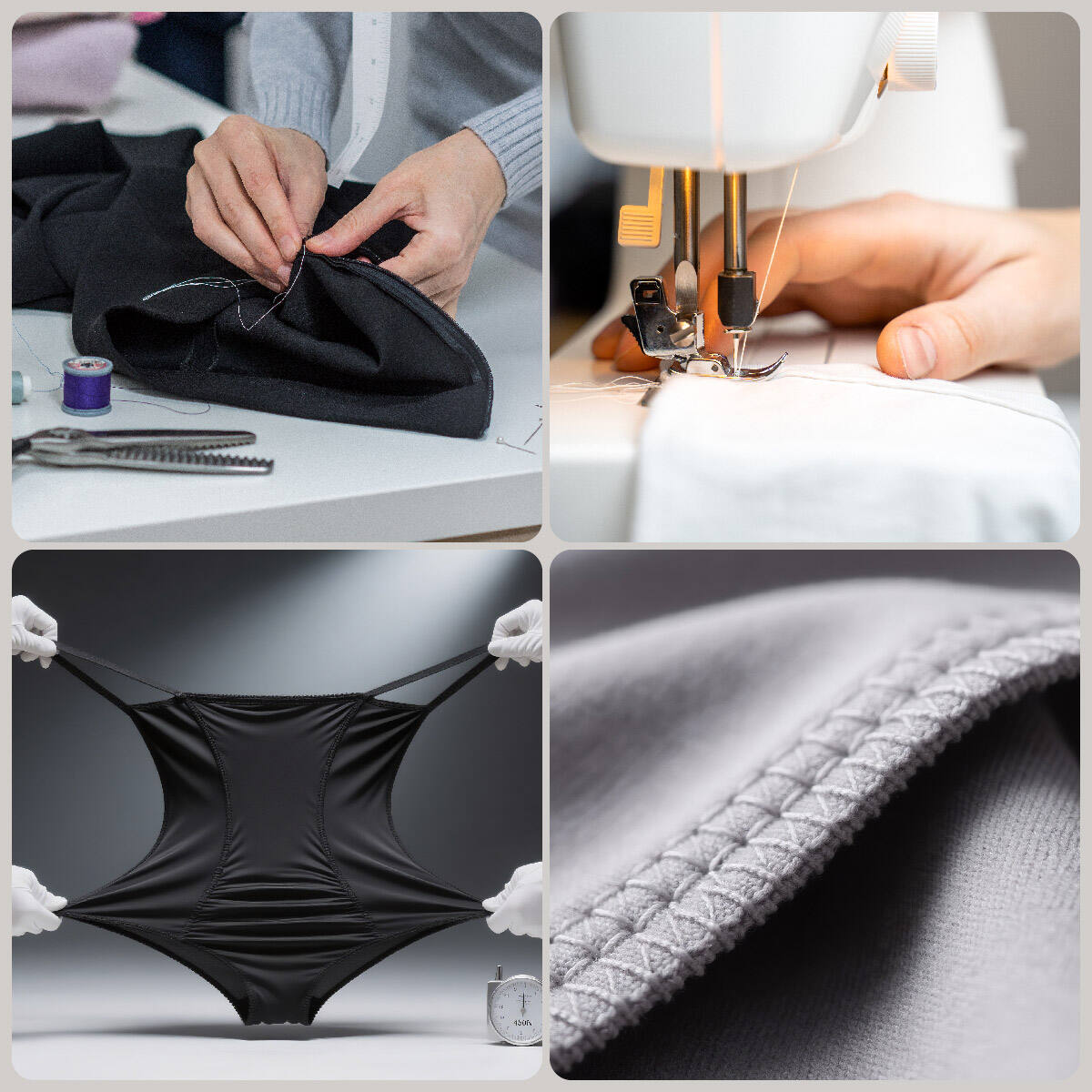

이 여정은 고급 원단 선택부터 시작됩니다. 이 단계에서는 최고 품질의 소재를 면밀히 선정하여 착용감과 내구성을 동시에 보장하기 위해 총 28단계의 상세한 원단 제조 공정이 포함됩니다. 원단은 통기성, 신축성 및 내구성에 대한 테스트를 거쳐 고객이 기대하는 높은 수준의 기준을 충족시켜야 합니다.

다음으로 몰드 컵 제작은 40개의 전문 공정을 따릅니다. 몰드 컵은 신체의 형태를 잡아주고 지지해주는 역할을 하므로 정밀하게 제작하는 것이 무엇보다 중요합니다. 모든 몰드는 여러 단계의 품질 검사를 거쳐 의류의 실루엣 기능에 기여하며, 지정된 체형에 적합하게 설계되었는지 확인합니다.

기본적인 부품들이 준비되면, 압박 속옷은 70단계의 재단 및 봉제 공정을 거칩니다. 여기에는 네 개의 바늘과 여섯 개의 실을 사용하는 복합적인 봉제 기술이 포함되며, 이는 견고함을 제공할 뿐만 아니라 편안함과 내구성도 보장합니다. 특히 봉제선이 매끄러워 피부 자극이 없도록 신경 쓰이며, 움직임에 따라 변형되어도 봉제가 끊어지지 않을 만큼 유연하게 처리됩니다.

이 생산 과정 전반에 걸쳐 30가지 이상의 품질 검사 및 테스트 과정이 진행됩니다. 이러한 검사에는 수축률, 색상 견뢰도, 탄성, 세탁 후 내구성 등 다양한 특성을 평가하기 위한 물리적 및 화학적 테스트가 포함됩니다. S-Shaper의 테스트는 엄격한 600회 반복 후킹 테스트와 1,000회 스트레칭 테스트를 포함하여 업계 표준을 뛰어넘는 엄격한 테스트를 통해 최종 제품이 시간이 지나도 우수한 성능을 유지하도록 보장합니다.

기존의 품질 관리 프로세스 외에도, S-Shaper의 쉐이프웨어는 최소 100명 이상의 사람들에 의한 실제 착용 테스트 및 평가를 거칩니다. 이 단계를 통해 각 제품이 실제 사용 조건에서 테스트되어 대량 생산 전 추가적인 개선이 이루어집니다. 이러한 엄격한 기준을 준수하고 진화적인 품질 관리 접근 방식을 채택함으로써 S-Shaper는 모든 제품이 단순히 스타일리시하고 지지력 있는 것을 넘어 일상 착용에 있어 내구성과 편안함을 갖추도록 보장합니다.

S-Shaper의 포괄적인 제조 및 테스트 프로세스는 고객에게 최고의 쉐이프웨어를 제공하려는 회사의 약속을 반영하며, 모든 제품이 자신감과 만족감을 전달하도록 보장합니다.

핫 뉴스

핫 뉴스