| PRODUCT DESCRIPTION |

| Color |

Black/Beige/Acceptable customization |

| Size |

S/M/L/XL/2XL/3XL/Acceptable customization |

| Material |

51%Nylon, 49%Spandex |

| Feature |

Breathable/Soft/Skin-friendly/Quick dry/Comfortable |

| Condition |

In stock / Make to order |

| Package |

1 pcs/ OPP Bags (Accept OEM Design Package) |

| Payment |

T/T,L/C, e-Checking,Credit Card and so on |

| Delivery time |

Samle/ 5-7 days, bulk/ 25-35days |

| Wholesale |

Welcome to contact with us to get wholesale price

We will offter best service for you

|

Shapewear fabric customization

Custom shapewear requires a variety of high-performance fabrics , such as tricot, brushed, rib, Lycra/spandex, sportswear fabric, knitted fabric, fleece terry, and patterned textiles. These fabrics are pre-tested for elasticity, softness, durability, and support to ensure optimal wearability and shaping effect.

Shapewear for Different Body Parts

Shapewear is often crafted to target specific areas of the body, providing tailored support, compression, and contouring where it is most needed. This customization allows wearers to address their unique shaping goals and achieve a smoother silhouette under clothing.

How to choose the pressure level of body shaping clothes

Choosing the right pressure (compression) level of body shaping clothes depends on your comfort preferences, shaping goals, and the occasion. Here’s a clear guide based on expert shapewear brands and industry standards:

| Compression Levels and Their Uses |

| Compression Level |

Description |

Best For |

Comfort & Wearability |

Light

Compression

|

Gentle smoothing andminimal shaping |

Everyday wear, beginners,

minor imperfections

|

Very comfortable, barelynoticeable, ideal for all-day wear |

Medium

Compression

|

Moderate shaping andcontouring with firm but flexible support |

Daily use and specialoccasions, smooths waist,tummy, thighs |

Comfortable enough forextended wear, enhancessilhouette noticeably |

Firn

Compression

|

Strong shaping andcontouring, flattensabdomen, lifts curves |

Formal events, when youwant a more dramatic transformation |

More restrictive but stillwearable for hours iffitted properly |

Extra Firm

Compression

|

Maximum control andshaping, highest level ofcompression |

Special occasions like

Post-surgical, weddings or cocktail parties

|

Least comfortable, should beworn for shorter periods.requires proper fit |

How Post-operative Sleeves is made Post-operative compression sleeves are made from flexible, elastic fabrics like nylon and spandex, combined with inflatable chambers to provide targeted compression. The manufacturing process involves layering durable, stretchable materials to create the sleeve’s base, into which inflatable bladders or chambers are inserted. These chambers connect to an external pump that inflates and deflates them rhythmically, improving blood flow, reducing swelling, and preventing complications such as deep vein thrombosis. Structural supports may be added to maintain shape and distribute pressure evenly. Precision stitching ensures durability and comfort, with soft inner finishes to minimize skin irritation. Connectors and tubing are integrated to link the sleeve to the pneumatic pump system. Post-operative sleeves undergo strict testing for safety, functionality, and biocompatibility. Some models are designed for reuse after proper disinfection. Overall, these sleeves combine elastic fabric and engineered compression technology to aid recovery by promoting circulation and reducing post-surgical swelling.

How to ensure product quality

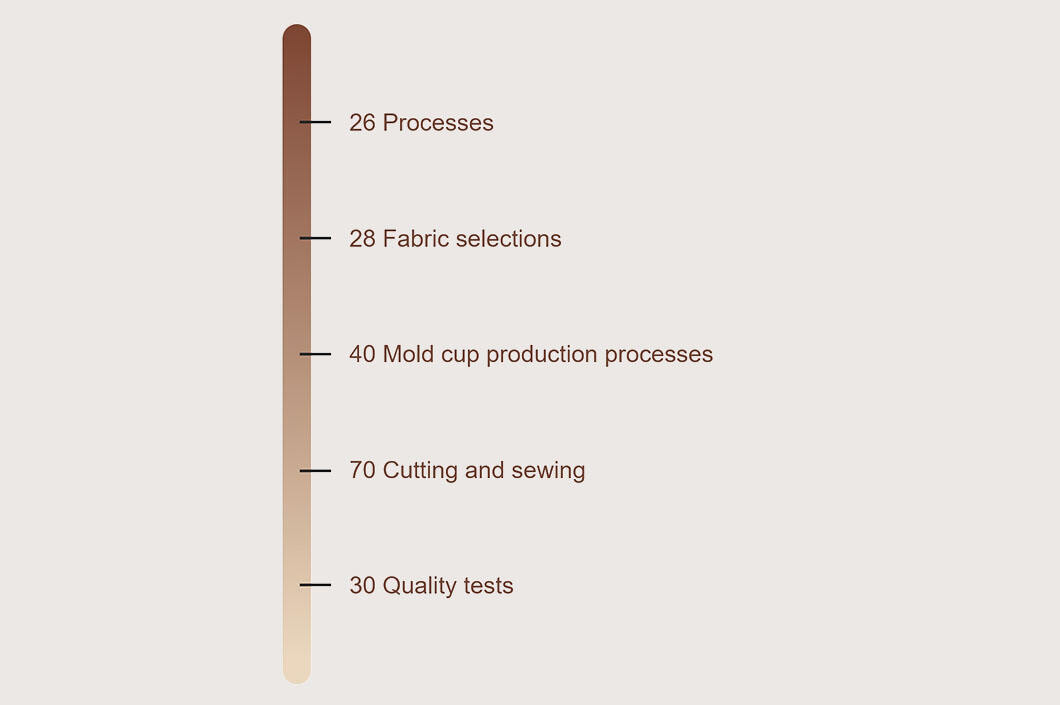

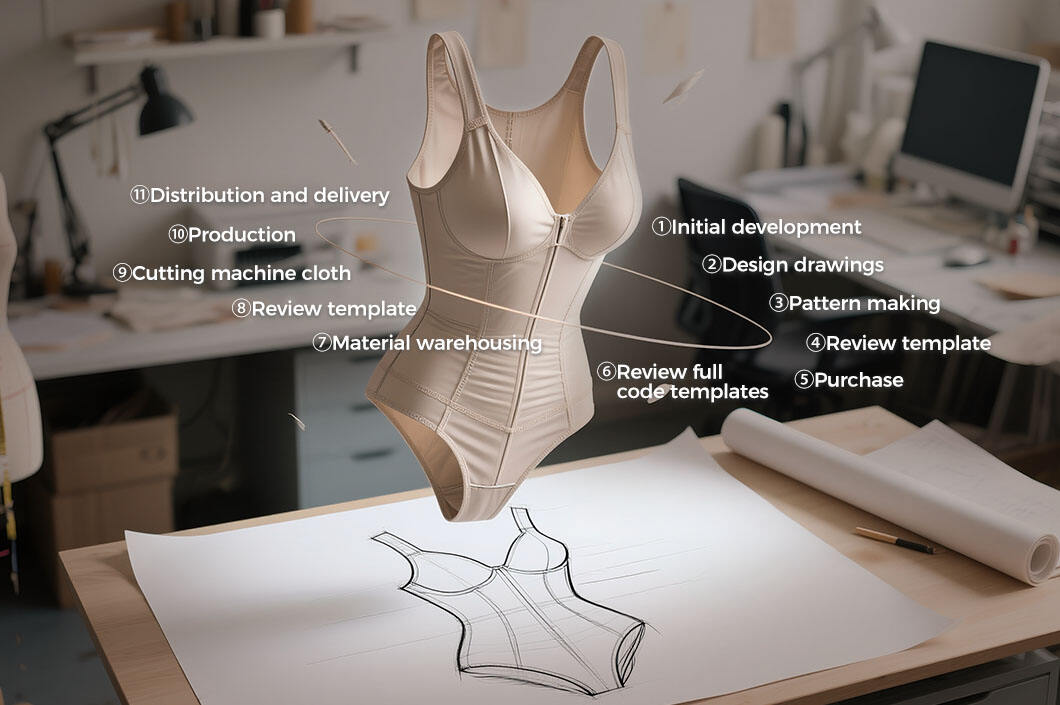

The production of a piece of shapewear goesthrough26 processes, including 28 fabric selectionandproduction processes, 40 mold cupproductionprocesses, 70 cutting and sewingprocesses,more than30 qualityinspection andtesting processes, andphysical and chemical testingprocesses. ensure that every product is of the best quality.

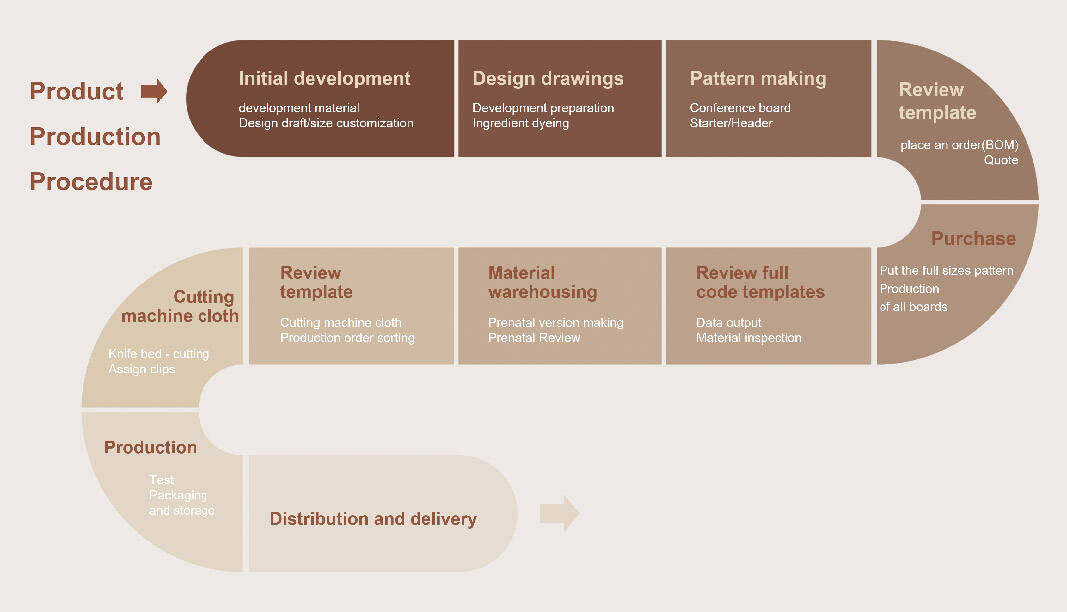

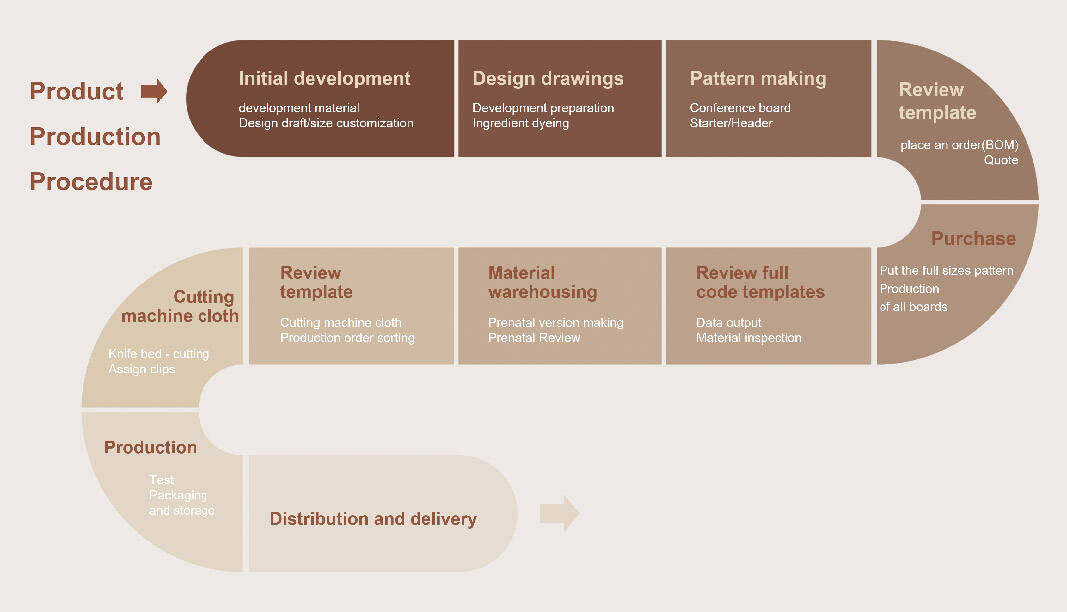

Helping Our Partners Succeed